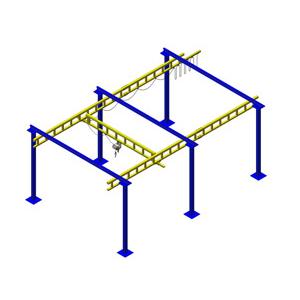

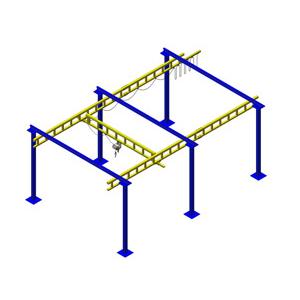

Used for material transportation between work units, it is simple and reliable to use, easy to move, precise in positioning, and minimizes the labor intensity of workers. High quality cold-rolled steel sections and reinforced truss structures ensure reliable and safe operation, and can guarantee a longer service life with minimal maintenance.

Flexible KBK rail crane

It is composed of main components such as supporting columns, attached beams, running tracks, main beams, electric

hoists, and power supply systems. It can quickly and safely complete the flat lifting operation of various materials, and its walking mechanism is very light in weight, easy to operate, and can move freely. It can also be simply suspended on the top structure of the factory building without the need for additional columns, improving space utilization while also having good economy.

1. The structure itself;

Rigid combination type: The connection between I-beam and profile rail, as well as the connection between profile rail and main beam, is rigid< Br/>

Flexible KBK track: The connection between I-beam and track, as well as the connection between track and main beam, is flexible;

2. Support center (column center distance);

Rigid combination type: self-supporting type: 6m-9m; Suspension type: 1.6m-9m< Br/>

Flexible KBK track: It is related to the lifting weight, usually 30cm-3m;

3. Main beam span;

Rigid combination type: up to 9m, with a main beam length of up to 10m< Br/>

Flexible KBK track: related to lifting capacity, 1 ton: 7m, with a main beam of 8m; 2 tons: double beam, electrically operated;

4. Clearance height;

Rigid combination type: embedded hanger, saving headroom< Br/>

Flexible KBK track: higher headroom with relatively small elevation;

5. Walking;

Rigid combination type: The main beam moves left and right together, making it easy to locate< Br/>

Flexible KBK track: asynchronous walking, difficult to locate;

6. Requirements for rigid structures;

Rigid combination type: with a truly self-supporting structure; The longer support center saves steel structure< Br/>

Flexible KBK track: requires an additional set of steel structure support; Suspension type requires more steel structures;

Difference 1: Safety of Hangers

Rigid connection, not easy to loosen or fall off< Br/>

Flexible connection, pins are prone to cracking and causing the track to fall;

Difference 2: Safety of shaped rail cars

The planning of the side wing plates of the rigid rail car can ensure a reliable connection between the car and the fixed rail. Even if the wheels of the rail car are damaged after several years of use or in extreme situations, the side wing plates can still be safely stuck on the fixed rail and will never fall off. Ensure that the connection between the small car and the fixed rail is definitely reliable< Br/>

The flexible KBK track car has no safety device planned, and once the wheel axle cracks, the car will fall off the track as a whole.